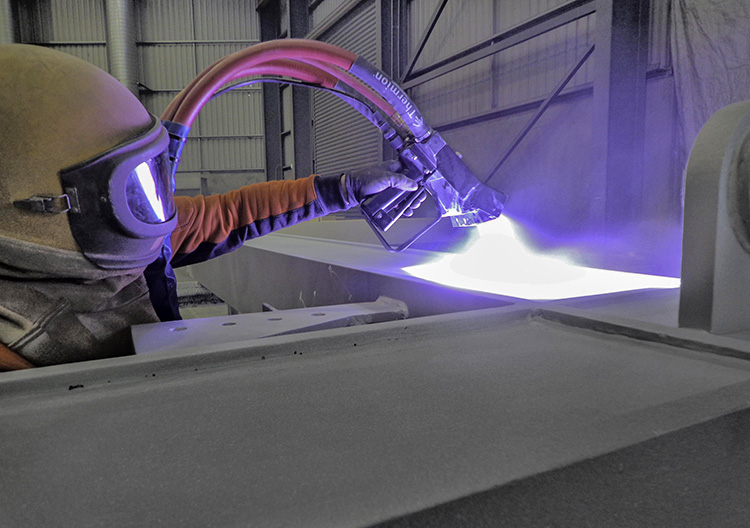

Metallisation is a general term that refers to the application of a Metal Coating to other metallic or non-metallic surfaces. Depending on the desired result, the coating can consist of metals such as Zinc or Aluminium.

The metallisation process can protect the work piece from damaging external forces (corrosion, wear, weathering, etc.), improve the appearance of the object or enhance the finished product’s functionality. Industries that use metallisation in their manufacturing processes include Aerospace, Automotive, Oil and Gas, Defence, Electrical and many others.

Pure metal or any composite with required proportionate, can be used in wire form for hot spray metalizing process. No distortion in parent metal with masking specific area is the key of hot spray metalizing process.

Ashirwad carries 35+ Years of expertise in the field of Metalizing, offering industry-leading quality and cost-effective options designed to achieve the needs of our customers.

Zinc Spray Galvanization is process where a coating is applied to a steel surface by spraying it with atomized particles of molten zinc. This is done by projecting the particles onto the abrasive surface using a handgun applicator or a special flame. The zinc coating provides excellent corrosion resistance for steel and iron objects and structures used in various environments such as Marine, Industrial and other unfavorable atmospheric conditions.

This process is suitable for structural components which cannot be dipped into a galvanizing bath due to large size and for objects that would become distorted during hot-dip galvanizing. The method is also used on sections of objects that cannot be accessed by dip galvanizing.

GET IN TOUCHAluminizing is a thermo-chemical diffusion treatment where in the surface layer of the material is impregnated with aluminum. It is primarily used on steels, but also on nickel and cobalt based alloys to obtain greater creep resistance, hardness and corrosion resistance.

The aluminizing process is usually operating at a relatively high temperature of 800–1000°C with prolonged soaking time taking into account the diffusion concept.

GET IN TOUCH

Established in the year 1995, Ashirwad Innovative Coating Private Limited is a prominent firm engaged in rendering excellent Industrial Blasting & Coating Services. Besides this, we offer Flooring and Painting Services to our patrons as per the clients' demands.

GET IN TOUCH